Implant Surface Treatment

Hybrid

To the neck

Hybrid surface treaty and even the neck

To reduce mechanical times for osseo-integration, different physical-chemical surface treatments are used, which modify the surface of the titanium machined on the lathe.

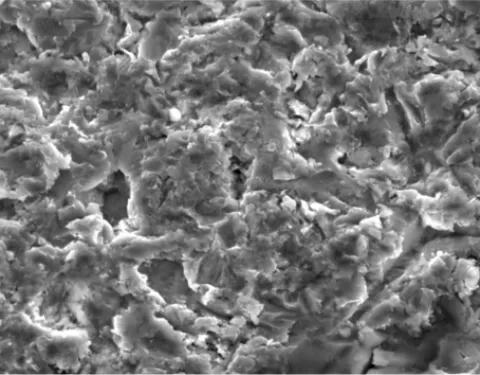

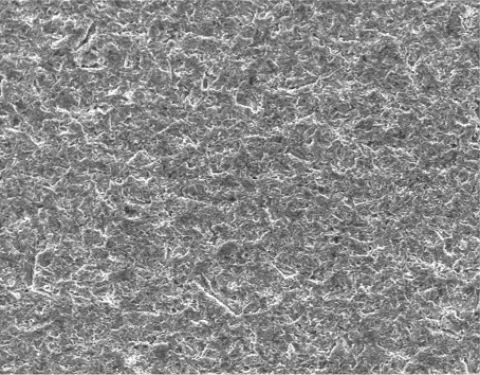

After treatment, the implant surface presents a roughness made up of macro and micro-pores of random orientation, whose metric characteristics are scientifically determined to achieve an increase in the total contact surface between the bone and the implant (BIC Bone to lmplant Contact).

The specific treatment for our implants is based on the projection of particles, (Shot-blasting Grift-blasting) added to a subsequent treatment of selective acid and coating.

The surface treatment allows to achieve excellent wettability of the bio-active proteins.

ANMAT has certified and validated the useful life of our Implants, for a duration of 10 years, from the date of manufacture in their original packaging.

PM Number: 2196-3/ 2196-4

Authorizing or Revalidating Provision: 8826-16

ANMAT Provision N• 9688/19

Packaging System

Each component manufactured is the result of precision engineering and inspection processes and international manufacturing practices.

The packaging of our implants goes through rigorous quality control and aseptic assurance in all its stages, which allows us to ensure products of the highest clinical reliability, providing the satisfaction of both patients and professionals.

Presentation